Key product feature

● High performance flux vector control for IM and PMSM (AD800S can compatible PMSM)

● Excellent quick response with vector control

● High starting torque even under low speed.

● Torque limit for machine safety protection

● Rapid current limit, up to 20 kinds protection function.

● Latest generation Infineon IGBT modules using

Features of products.

It has V/F, OLV( open loop vector control ), CLV ( close loop vector control), Compatible with variety of encoder such as collector, differential / rotary transformer.

1). Wide speed control range

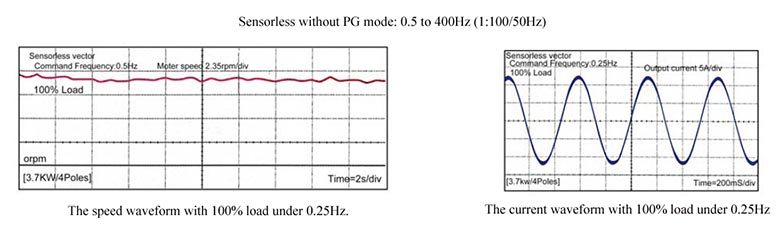

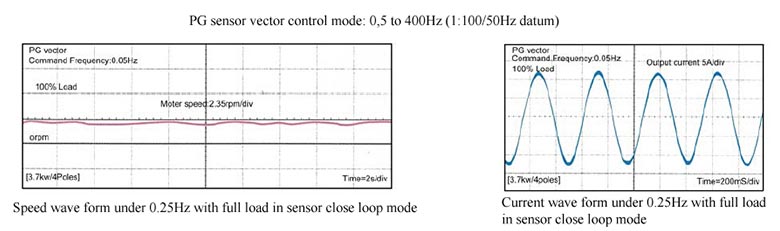

a). Sensorless open loop vector (OLV) control: 0.5 to 400Hz ( 1:100/50Hz datum point )

b) . Sensor with PG card: 0.5 to 400Hz ( 1:100/50Hz datum point) Good current waveform

2). Response speed improving

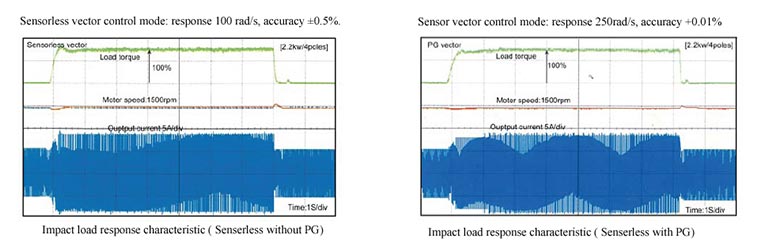

Adopting high speed 32 bit DSP to get the high speed response of frequency inverter.

a.) The response 100rad/s, precision ± 0.5% in sensorless open loop vector control mode.

b.) The response 250rad/s, precision ± 0.01% in sensor close loop vector control mode

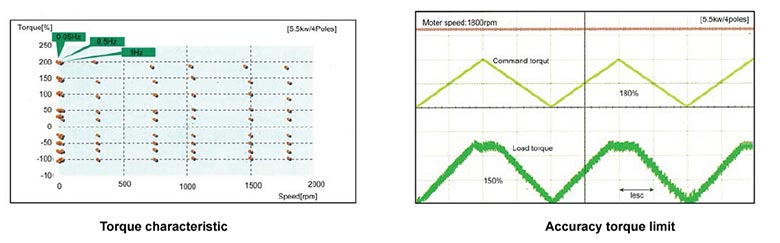

3). High torque output under low speed to meet some big inertia load conditions

High torque under low speed achievement.

Adopting advanced current vector control technology and motor parameters detecting to make high torque under low speed is available.

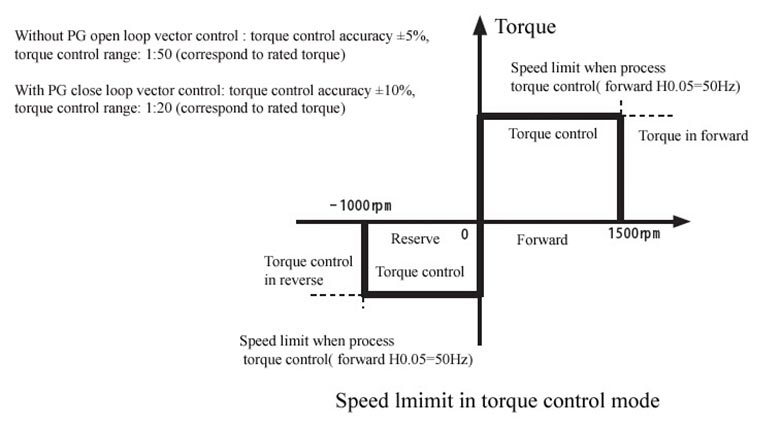

4). Torque control in OLV and CLV

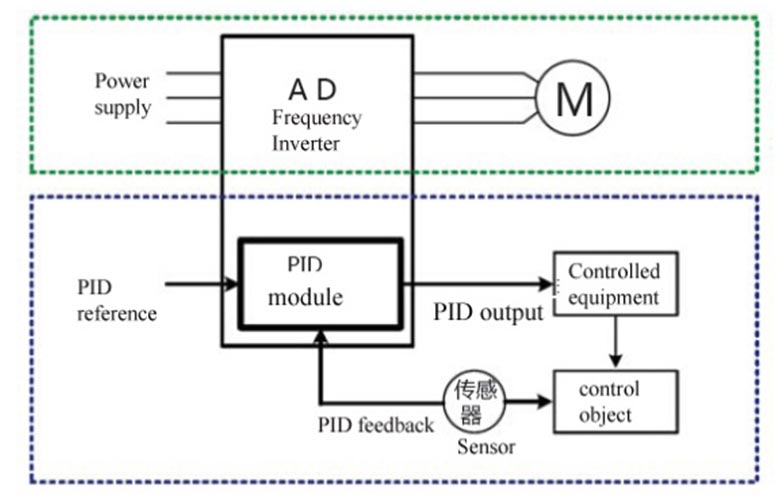

5). Powerful PID function

Possible to set PID1 and PID2 combination function, free switch between two PID parameters.

PID module can be used for external unit using with professional PID control.

Flexible PID control with sleep mode, configure waking up frequency, sleep frequency, that is very easy using for water supply.

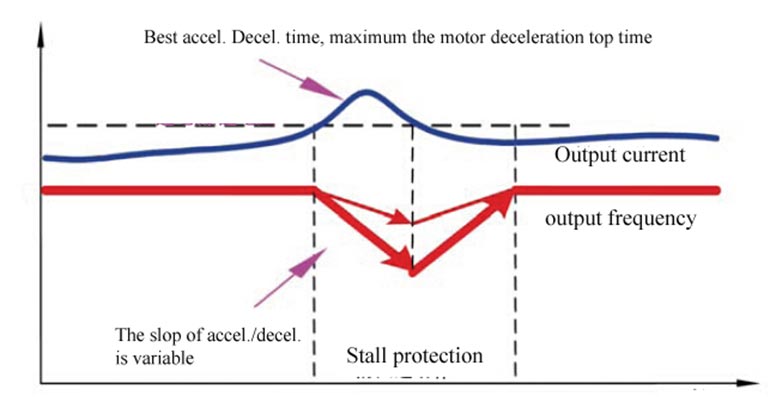

6). Stall protection function

when over current, over voltage occurs, the output frequency will be reduce, and the output frequency /voltage under limit value, the output frequency will restore.

Appropriate acceleration and deceleration will be select according to the load control the motor stopping time even power loss instantaneous.

Stall protection illustrations

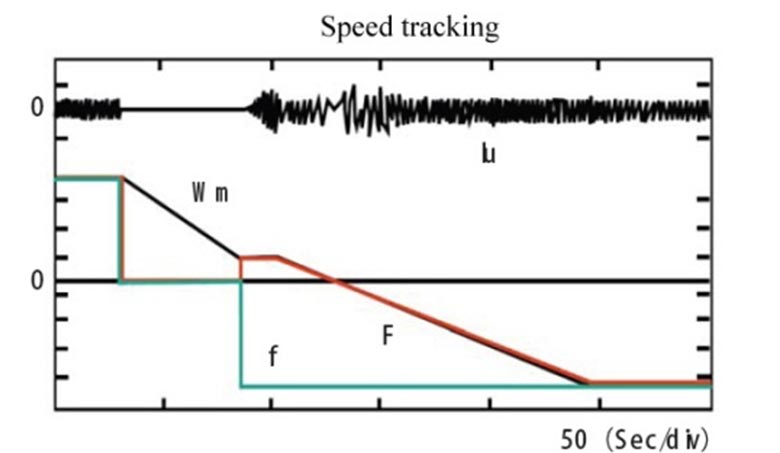

7). Speed tracking restart function

Detect motor speed and rotation direction automatically, no any trip during start even in reverse running status.

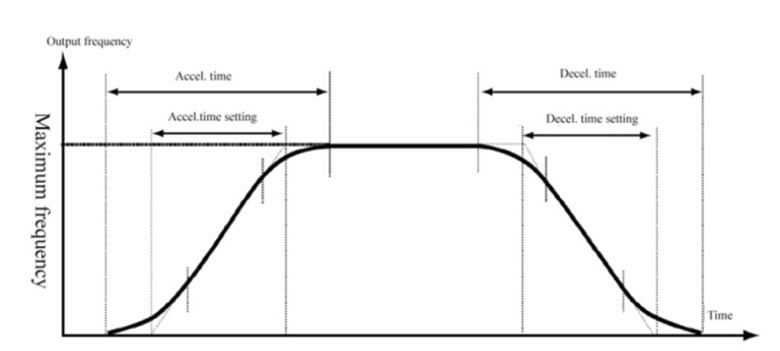

8). S curve function

S curve can improving the impact during the start and stop processing, it is very useful in crane, elevator application

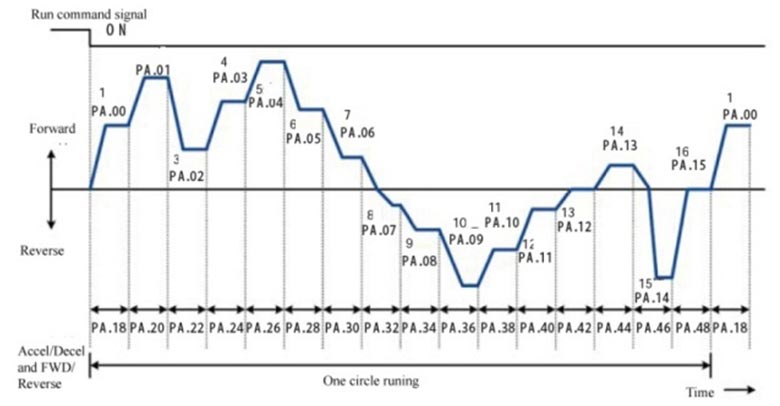

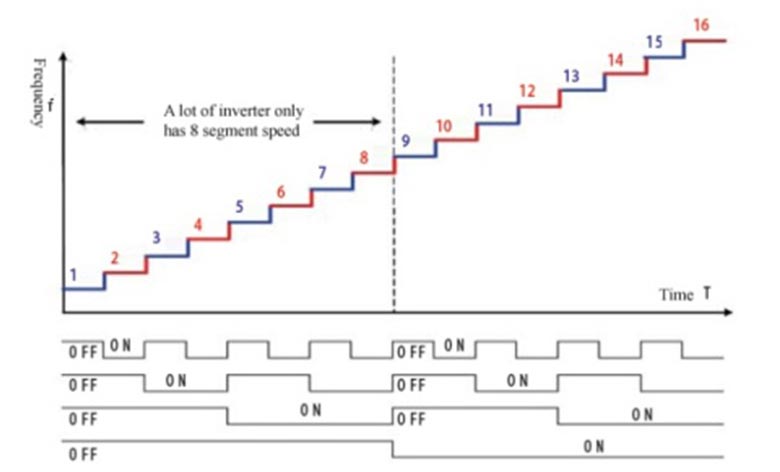

9). 16 segment speed circle running, easy to configure.

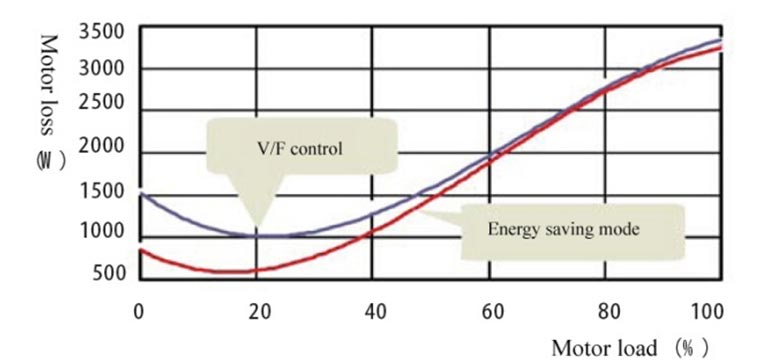

10). Advanced energy saving technology

AD800 series inverter can detect the load status to control the output voltage and power factor to make motor work in high efficient mode.

Single phase, 220V, 0.4kw to 7.5kw.

Three phase, 220V, 0.75kw to 75kw

Three phase, 380V/660V/1140V, 0.75 to 710kw.

| Items | Specification | |||

| Control mode | Control mode | SVC in open loop | V/F control | Close loop vector control |

| Starting torque | 0.5Hz 180% | 0.5Hz 150% | 0.00Hz 180% | |

| Speed adjust range | 1:100 | 1:100 | 1:1000 | |

| speed stabilizing | ±0.02% | |||

| precision | ||||

| Torque precision | NO | NO | ±5% | |

| Motor type | General induction motor,permanent magnet synchronous motor* | |||

| Functin design | Highest frequency | General vector control :400Hz V/f control:4000Hz | ||

| frequency resolution | Digital setting: 0.01Hz analog setting: maximum×0.025% | |||

| carrier frequency | 0.5K~16KHz, the carrier frequency can be adjust by temperature automatically | |||

| Frequency reference setting method | Digital of Control panel, analog AI1, AI2, potentiometer of control panel, UP/DN control, communication, PLC pulse frequency | |||

| Accel./decel. characteristic | Linear curve and S curve accel. /decel. mode, range of time: 0.0 to 65000S. | |||

| V/F curve | 3 mode: linear, multiple points, N Power | |||

| V/F separation | 2 times separation: totally separation, half separation | |||

| DC braking | DC braking frequency: 0.0 to 300Hz, DC braking current: 0.0% to 100% | |||

| Braking unit | Built in braking unit up to 15kw, optional is 18.5kw to 75kw, external built in for above 93kw. | |||

| Jog function | Job frequency range: 0.0 to 50.0Hz, the accel. and decel. time of Jog | |||

| Configuration PID | Easy to perform pressure, flow, temperature close loop control | |||

| PLC multiple speed | To achieve 16 segment speed running through built in PLC or terminal control | |||

| Common Dc bus * | Multiple inverters use one DC bus for energy balance. | |||

| Auto voltage regulation (AVR) | Enable to keep output voltage constant when grid fluctuation | |||

| Over load tolerance capability | G type model: 150% rated current for 60s, 180% rated current for 2s, | |||

| P type Model: 120% rated current for 60s, 150% rated current for 3s. | ||||

| tall control when over current, over voltage | Carry out limiting automation for running current, voltage to prevent over current, over voltage frequently | |||

| Fast current limit function | minimize the IGBT module broken to protect the inverter, maximum reduce the over current fault. | |||

| Torque limit and torque control | "Excavator" characteristics , torque limit automatically during motor running. Torque control is available in close loop vector control mode. | |||

| features | friendly interface | Display Hello when power on. | ||

| Multiple function key JOG button | It can set for Forward Jog, reverse Jog, forward/reverse switch | |||

| Timing control function | A total running time and total running time calculating | |||

| 2 group motor parameters | To achieve two motor switching freely, control mode is selectable | |||

| Motor over heat protection | Accepting motor temperature sensor signal input via AI1 terminals. | |||

| Multiple kinds encoder * | Compatible collector, difference, and rotary transformer Encoder. | |||

| Command source | Control panel, control terminals, series communication, switch freely. | |||

| Frequency source | Digital setting, analog current/voltage, pulse setting, serial communication, main and auxiliary combination. | |||

| Protection function | Short circuit detect after power on, input/output phase missing, over voltage, over current, under voltage, over heat, over load protection. | |||

| Environment | Application site | Indoor, free of exposure to sunlight, no dusty, no corrosive, no inflammable gas, no oil and water vapor, and water dipping | ||

| Altitude | Lower 1000m | |||

| environment temperature | -10℃~+40℃, power derate for 40~50℃, rated current derated 1% for 1℃increasing. | |||

| humidity | Less than 95%, no water condense. | |||

| storage | -40~+70℃ | |||

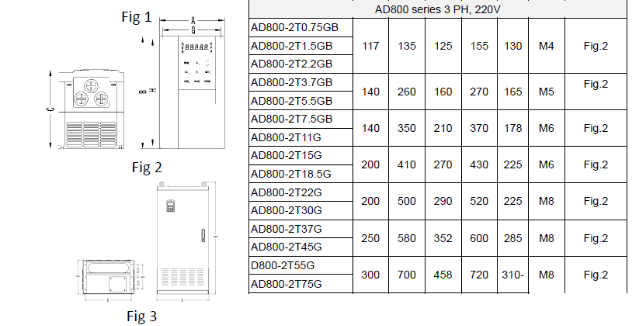

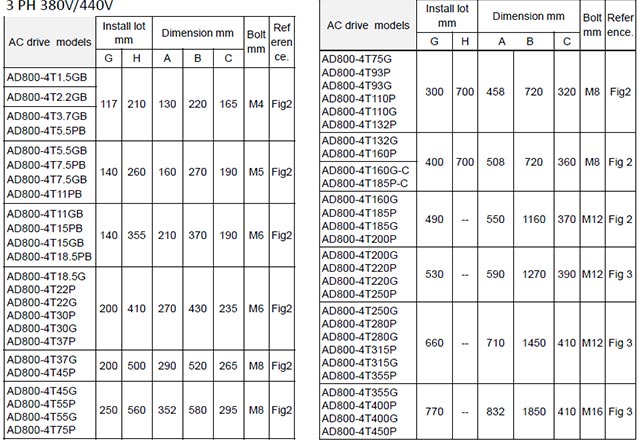

AD800 AC Drive models.

AD800 Inverter Data sheet.

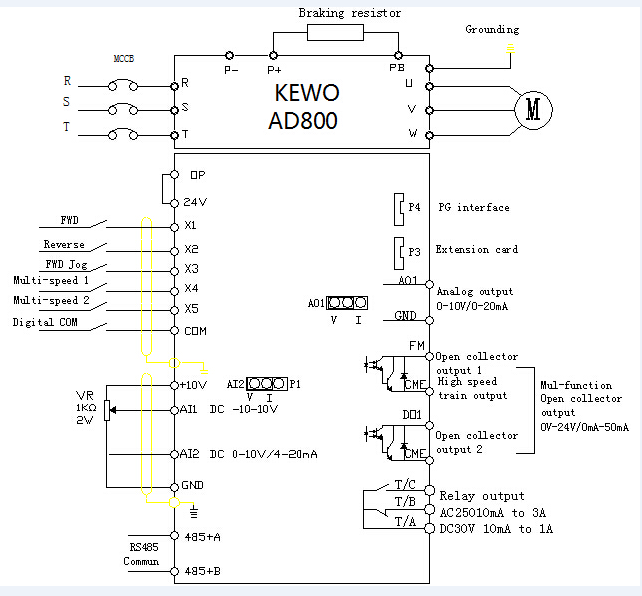

Wiring diagram of AD800.

1. PG cards external built if need, support ABZ optical encoder, ABZ differential input, Rotating transformer encoder...)

2. Built in following functions terminals.

● It has 5 digital I/O input, compatible with sink and source way. (NPN /PNN)

● 2 Analog input, support -10V to 10V, 0-10V, 0/4 to 20mA.

● 1 Analog output ( 0-10V/0-20mA cab be selected)

● 2 collector output ( FM and CME support the high pulse output).

● 1 relay output. ( if need two relays please built external card)

● Rs485 communication card.( 485+, 485-)

● Extension card is available. ( 4 digital terminals, 24V power supply, OP ( external power supply terminal,1 analog output , and 1 relay output )

AD series high performance inverter better being used in various application with high accuracy speed control quick torque response and starting torque.

Textile: P-jump Winders, Extruders, Tufting Machines, spinning machine

Packaging: In-feed / Out-feed, Case Packing, Bottling & Canning, Carton Manufacturing. Beverage packing

Plastics & Rubber: Extruders, Blow Molding, Thermoforming, Injection Molding.

Pulp & Paper: Paper Machines, Debarkers, Winders, Saw Mills

Converting: Coaters ,Laminators, Slitters, Flying Cutters

Air Handling: Supply and Return Fans, Cooling Towers, Spray Booths, Dryers

Oil & Gas: Top Drives, Pumpjacks, Down-hole Pumping Centrifuges

Material Handling: Conveyors, Sortation, Palletizers, Coil Winding

Metals: Stamping / Punch Press, Wind /Unwind, Cut-to-length, cable drawing.

Wire Draw

Construction Materials: Kilns, Planers, Flying Cutoff, Mixers

Laundry: Dryers, Extractors, Folders, Washers

Food & Beverage: Conveyors, Fillers, Mixers, Centrifuges

Automotive: Stamping, Test Stands, Indexing, Metal Cutting

Construction crane, hoist, lifting