The frequency converter controls the speed of industrial fans by altering the power frequency and voltage of the motor. The specific process is as follows:

1. Working Principle

The frequency converter transforms the standard AC power supply (e.g., 50Hz or 60Hz) into an AC power supply with adjustable frequency and voltage. By modifying these parameters, the motor speed is adjusted, thereby controlling the airflow of the fan.

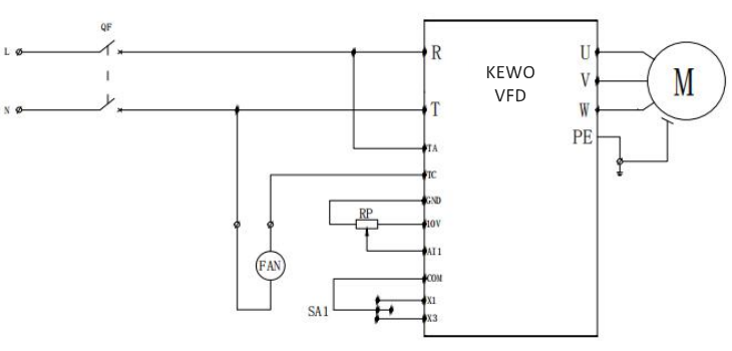

2. Connection Steps

Power Connection: Connect the input terminal of the frequency converter to the standard power supply (e.g., 380V/50Hz).

Motor Connection: Connect the output terminal of the frequency converter to the motor of the industrial fan.

Control Signal Connection: Based on requirements, connect the control terminals of the frequency converter to the control system, such as a PLC or manual speed regulator.

3. Parameter Settings

Set the motor's rated power, voltage, current, and frequency.

Auto tuning

Please refer to user manual P0-11=12.0kHz, carrier frequency, carrier frequency above 3Hz (if the motor electromagnetic noise is large, it can be increased, generally around 12K)

Debugging many times, please contact us if there is any problem

4. Startup and Operation

Startup: After the frequency converter starts, it gradually increases the output frequency and voltage, allowing the motor to slowly accelerate to the set speed.

Operation: Based on the control signals, the frequency and voltage are adjusted in real-time to maintain the required speed.

Shutdown: During shutdown, the frequency converter gradually reduces the frequency and voltage, allowing the motor to decelerate smoothly to a stop.

5. Advantage

1. All-in-one machine, no need for distribution box, saving installation time;

2. Mute control, support up to 16K carrier frequency.

3. High appearance and simple operation.

4. Parameters are packed without debugging.

5. Speed tracking is on.

6. More energy efficient.

Model Selection

1. FI300 series (Metal shellIP65)

Model No. | Voltage | Power | Current |

FI3002S0.75G | 220V | 0.75KW | 4A |

FI300-2S1.5G | 220V | 1.5KW | 7A |

FI300-2S2.2G | 220V | 2.2KW | 10A |

FI300-4T1.5G | 380V | 1.5KW | 3.7A |

FI300-4T2.2G | 380V | 2.2KW | 5A |

2. FI110 series (Plastic shell IP65)

Model No. | Voltage | Power | Current |

FI110-2S0.75G | 220V | 0.75KW | 4A |

FI110-2S1.5G | 220V | 1.5KW | 7A |

FI110-2S2.2G | 220V | 2.2KW | 10A |

FI110-4T1.5G | 380V | 1.5KW | 3.7A |

FI110-4T2.2G | 380V | 2.2KW | 5A |

VFD wiring diagram: