Multiple starting modes

Current-limiting start, ramp current-limiting start and voltage ramp start can meet the site requirST100ents to the maximum extent and realize the best starting effect.

High reliability

High performance microprocessor conducts digital processing for signals in control systST100, avoiding the excessive adjustment to analog line so as to obtain the best precision and execution speed.

Powerful anti-interference performance

All external control signals adopt optoelectronic isolation and are set with different anti-noise levels. The device is applicable for use in special industrial environment.

Optimized structure

The unique compact structure is designed to be easily integrated into user’s existing systST100, saving expenses for restructuring of systST100.

Motor protection

Multiple motor protection functions such as over-current, input/output phase-failure, short circuit of thyristor and overheat protection can guarantee motor soft starter not to be damaged in case of fault or incorrect operation.

Easy maintenance

Pilot signal coding systST100 composed of 4-digit number display monitors working condition

Typical Applications

• Bow Thruster, • Compressor, • Elevator, • Centrifugal pump

• Conveyor belt • Mixer, Centrifugal fan, • Crusher • Mill

• Conveyor belt (long) • Stirrer

Control power: AC110V--220V+15%

Three-phase power supply: AC380V, 660V, 1140V±30%

Nominal current: 15A-----1000A, totally 22 kinds of rated values.

Applicable motor: General squirrel cage asynchronous motor.

| ST100 | Description | |

| Input Power Supply | Input Voltage | Three-phase 220V/380V/480V/660 AC |

| Frequency | 50/60Hz | |

| Adaptive Motor | Squirrel-cage three-phase asynchronous motor | |

| Starting Times | It is recommended not to exceed 20 times per hour. | |

| Control Mode | (1) Operation panel control. (2) Operation panel + external control. | |

| (3) External control. (4) External control + COM control. | ||

| (5) Operation panel + external + COM control. (6) Operation panel + COM control. (7) COM control. (8) No start or stop operation. | ||

| Start Mode | (1) Current-limiting to start. (2) Voltage ramp to start. (3) Torque control + current-limiting to start. (4) Torque control + voltage ramp to start. | |

| (5) Current ramp to start. (6) Voltage current-limiting double closed-loop start. | ||

| Stop Mode | (1) Soft stop. (2) Free stop. | |

| Protective Function | (1) Open loop protection for external instantaneous stop terminals. | |

| (2) Over-heat protection for soft starter. | ||

| (3) Protection for too long starting time. | ||

| (4) Input open phase protection. | ||

| (5) Output open phase protection. | ||

| (6) Unbalanced three-phase protection. | ||

| (7) starting over current protection. | ||

| (8) Running overload protection. | ||

| (9) Under voltage protection for power voltage. | ||

| (10) Overvoltage protection for power voltage. | ||

| (11) Protection for fault parameter setting. | ||

| (12) Load short circuit protection. | ||

| (13) Auto restart or incorrect wiring protection. | ||

| (14)Incorrect wiring protection of external control stop terminals. | ||

| Ambient | Place to be used | Indoor location with good ventilation free from corrosive gas and conductive dust. |

| Altitude | Below 1000M. It have to rise the rate power when the altitude is more than 1000M. | |

| TST100perature | -30 +55 oC | |

| Humidity | 90%RH without dew condensation. | |

| Vibration | <0.5G | |

| Structure | Protection Class | IP20 |

| Cooling Pattern | Natural wind cooling. | |

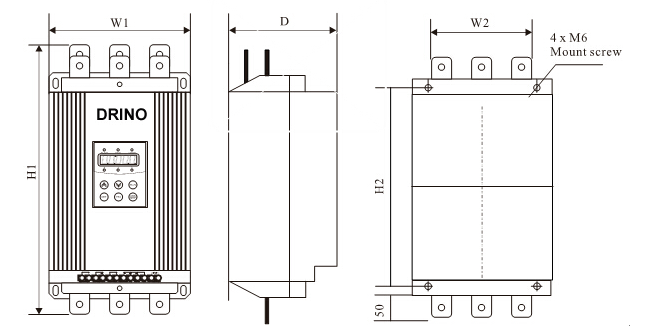

| Dimensional drawing Mounting holes schST100atic | |||||||||||

| Model | Power | Current | External Dimensions (mm) | Installation Dimensions (mm) | N.W | ||||||

| 220V | 380V | 480V | (KW) | (A) | H1 | W1 | D | H2 | W2 | d | (K.G) |

| ST100-GJ2-045 | ST100-GJ3-090 | ST100-GJ4-090 | 45/90 | 180 | 515 | 257 | 198 | 382 | 192 | M9 | <21 |

| ST100-GJ2-055 | ST100-GJ3-115 | ST100-GJ4-115 | 55/115 | 230 | 515 | 257 | 198 | 382 | 192 | M9 | <21 |

| --- | ST100-GJ3-132 | ST100-GJ4-132 | 132 | 264 | 515 | 257 | 198 | 382 | 192 | M9 | <21 |

| ST100-GJ2-075 | ST100-GJ3-160 | ST100-GJ4-160 | 75/160 | 320 | 515 | 257 | 198 | 382 | 192 | M9 | <21 |

| ST100-GJ2-090 | ST100-GJ3-185 | ST100-GJ4-185 | 90/185 | 370 | 515 | 257 | 198 | 382 | 192 | M9 | <21 |

| ST100-GJ2-100 | ST100-GJ3-200 | ST100-GJ4-200 | 100/200 | 400 | 515 | 257 | 198 | 382 | 192 | M9 | <21 |

| ST100-GJ2-132 | ST100-GJ3-250 | ST100-GJ4-250 | 132/250 | 500 | 515 | 257 | 198 | 382 | 192 | M9 | <21 |

| ST100-GJ2-160 | ST100-GJ3-280 | ST100-GJ4-280 | 160/280 | 560 | 515 | 257 | 198 | 382 | 192 | M9 | <21 |

| ST100-GJ2-185 | ST100-GJ3-320 | ST100-GJ4-320 | 185/320 | 640 | 560 | 285 | 248 | 460 | 260 | M9 | <25 |

| --- | ST100-GJ3-355 | ST100-GJ4-355 | 320 | 640 | 560 | 285 | 248 | 460 | 260 | M9 | <25 |

| ST100-GJ2-200 | ST100-GJ3-400 | ST100-GJ4-400 | 200/400 | 800 | 590 | 331 | 248 | 497 | 265 | M9 | <30 |

| ST100-GJ2-220 | ST100-GJ3-450 | ST100-GJ4-450 | 220/450 | 900 | 590 | 331 | 248 | 497 | 265 | M9 | <30 |

| ST100-GJ2-250 | ST100-GJ3-500 | ST100-GJ4-500 | 250/500 | 1000 | 665 | 410 | 248 | 547 | 345 | M9 | <42 |

| ST100-GJ2-315 | ST100-GJ3-600 | ST100-GJ4-600 | 315/600 | 1200 | 665 | 410 | 248 | 547 | 345 | M9 | <42 |

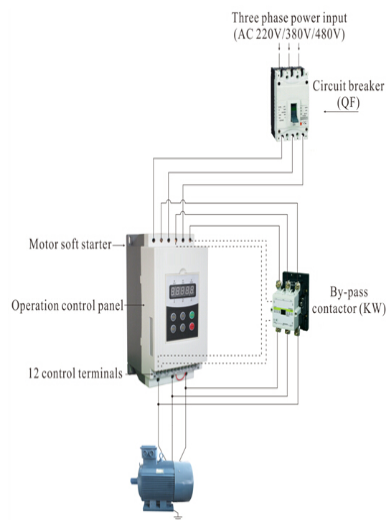

Application examples

The parameters of the different loads are different, please refer to below diagram

| The loading | Voltage ramp starting time(s) | Voltage ramp stopping time(s) | Initial voltage | Voltage ramp (current limit) | Current limit to start |

| Ball mill machine | 20 | 6 | 60% | 400% | 350% |

| Fan | 26 | 4 | 30% | 400% | 350% |

| Centrifugal | 16 | 20 | 40% | 400% | 250% |

| Piston compressor | 16 | 4 | 40% | 400% | 300% |

| hoister | 16 | 10 | 60% | 400% | 350% |

| Stirring machine | 16 | 2 | 50% | 400% | 300% |

| Breaker | 16 | 10 | 50% | 400% | 350% |

| Screw compressor | 16 | 2 | 40% | 400% | 300% |

| Rotating conveyor | 20 | 10 | 40% | 400% | 200% |

| Light load | 16 | 2 | 30% | 400% | 300% |

| Convey belt | 20 | 10 | 40% | 400% | 250% |

| Heat pump | 16 | 20 | 40% | 400% | 300% |