AD800Z is a special made VFD which suits to drive injection molding machine for saving, built in 0-1A signal converter card inverter, and uses big rate iGBTs, that good for heavy duty load.

This is item developed based on kewo high performance AD800 high performance vector control inverter.

AD 800 high performance vector control inverter can support open loop vector control, close loop vector control and VF control.

In generally, open loop vector control without encoder feedback is can service your IMM working very well. Because it can provide 150% rated torque under 0.5Hz, the torque response time is 100rad/s

And AD800Z has following features, which better for you IMM working, get more engineer saving.

1. Built in 0-1A to 0-10V or 0-10mA single converter card.

2. Configured H parameters special to fit injection molding machine running characteristic.

H parameters can use to adjust the running curve to improved the performance of IMM according to its process.

The output frequency can be adjust via the curve setting.

3. Stronger overload capability. 180% rated current for 1 min, 200% rated current for 0.5s.

| Parameters | name | setting value |

| P0.01 | control mode | 1 terminals control |

| P2.02 | motor power | per onsite motor |

| P2.04 | motor speed | per onsite motor |

| P2.27 | mootr auto tuning | 2 |

| P0.00 | runing motor | 0 open loop vector control |

| P0.03 | frequency reference | 2 IMM using only |

| P0.08 | acceleration time | per IMM |

| P0.09 | deceleration time | per IMM |

| P0.11 | carrier frequency | per IMM |

| P0.13 | factory restore | 1 |

| P3.08 | Vector control over excitation gain | 80 |

| PC.03 | Over voltage gain | 80 |

| PC.04 | Overvoltage protection voltage | 125 |

| PC.05 | Over current stall gain | 50 |

| PC.06 | Over current stall protection current | 140 |

| H3.00 | voltage value corresponding to 0% speed | |

| H3.02 | voltage value corresponding to 30% speed | |

| H3.04 | voltage value corresponding to 60% speed | |

| H3.06 | voltage value corresponding to 99% speed |

Generally only need to set two parameters

P0.03 for 2, and P0.01 for 1 if selecting with VF control

If need vector control for large torque under low speed, need to set motor parameters and motor auto tunning.

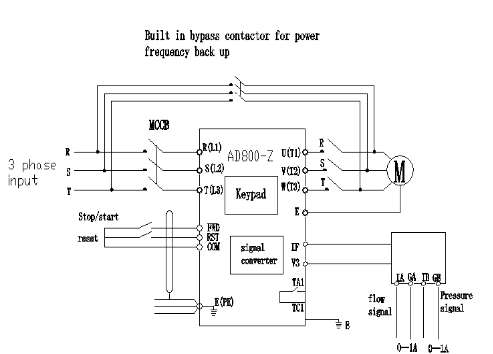

Wiring diagram of AD800.

Installed very easy only connect VFD to your motor before.

Suggest customer built power frequency by pass circuit to protect IMM runs with no stop

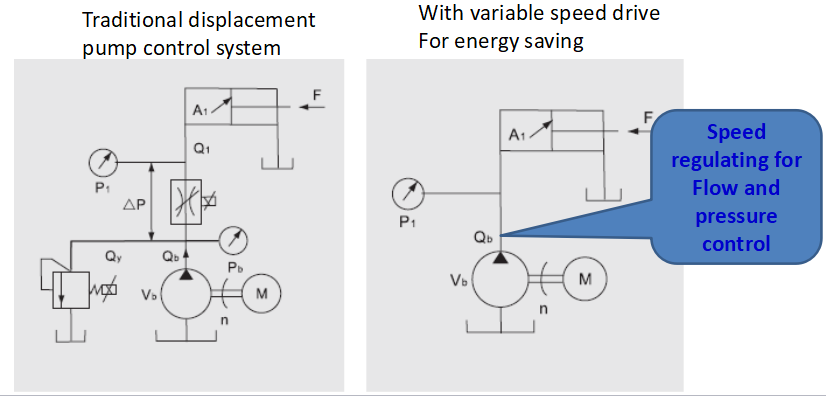

What is the benefit in injection molding retrofitting with VSD.

Injection Molding is a common method of plastic processing in which thermoplastic materials can be molded into arbitrary complex shapes, Most injection molding machines use complicated hydraulic systems to perform the necessary work of the process. Hydraulic system flow and pressure requirements vary throughout the cycle and in many cases, excess fluid that is not required by the process is throttled back to the reservoir, wasting motor energy and producing additional thermal load on the cooling system. variable speed drives can be used to allow injection molding machine hydraulic systems to vary the amount of fluid that is throttled, reducing the amount of wasted energy.